How Free-Form Lenses Are Made | Step-by-Step Lab Guide

Inside the Lens Lab: How Free-Form Lenses Are Made (Step by Step)

An expert, behind-the-scenes walkthrough of digital optical lens manufacturing.

Modern optical practices increasingly rely on digital free-form lenses to deliver higher clarity, improved patient comfort, and reduced remake rates. Yet few outside of a lab have seen how these lenses are actually made. Understanding this process helps optometrists, opticians, and practice managers make more informed recommendations, improve patient communication, and choose the right optical lab partner.

This step-by-step walkthrough takes you inside the manufacturing workflow at a high-precision, fully digital lab such as MIA LAB – an independent optical lab in Florida (Hialeah / Miami) known for its 24-hour turnaround, advanced free-form technologies, and strict quality control.

From the moment an Rx is submitted through platforms like VisionWeb or LabLink to the moment the finished lenses leave the lab, every step is engineered for optical accuracy down to the micron.

Step 1 – From Prescription to Digital Blueprint: How Free-Form Lens Design Begins

Interpreting the Prescription with Advanced Lens-Design Software

The process begins when the prescription enters the digital system. Unlike traditional surfacing, which applies the same design to all wearers, modern freeform lens manufacturing customizes every lens individually.

Using advanced design engines-such as IOT Digital Ray-Path® 2-the lab transforms the Rx into a personalized 3D optical map.

This algorithm evaluates:

- The patient’s gaze behavior

- Viewing angles and natural eye rotation

- Vertex distance, pantoscopic tilt, and wrap angle

- Frame dimensions and shape

- Prescription complexity

These calculations ensure that the final lenses are optimized for real-world use, not theoretical geometry. This is what makes digital freeform lenses radically more accurate and comfortable than older surfacing methods.

👉 Learn more about the lens technologies used at MIA LAB here

Step 2 – Digital Free-Form Surfacing: Creating a Custom Optical Surface

Turning a Blank into a Precision-Engineered Lens

Once the digital blueprint is complete, the lab moves to free-form surfacing, where state-of-the-art CNC machinery sculpts the backside of the lens with diamond-tipped tools.

During this stage:

- Micron-level layers of material are removed

- Each point on the lens surface is shaped according to the wearer-specific map

- Power distribution is adjusted for clarity at distance, intermediate, and near zones

- Aberrations are minimized across the entire field of view

This individualized approach produces the smooth, seamless gradients that define premium digital freeform progressive lenses.

Camber™ Dual-Surface Technology: Wider Near Zones and Smoother Optics

When a job calls for Camber™ progressive lenses, the lab uses a unique front surface with a variable base curve. Combined with back-side free-form optimization, this produces:

- Larger, ergonomically positioned reading zones

- Balanced intermediate fields ideal for computer use

- Reduced peripheral distortion

- Natural transitions for presbyopic wearers

Camber is one of the signature technologies powering MIA LAB progressive lenses, especially the advanced Remedy designs.

Step 3 – Polishing: Refining the Optical Geometry

After surfacing, the lens enters a multi-stage polishing process.

Polishing ensures:

- A perfectly uniform surface

- Smooth micro-geometry

- Reduced surface haze

- Improved clarity and contrast

- Optimal performance for progressives, where subtle imperfections can affect adaptation

For high index lenses, such as 1.67 or 1.74 high index lenses, precise polishing is even more critical because these materials are less forgiving of unevenness.

Step 4 – Coating Application: AR, Scratch-Resistant, UV, and Blue-Light Protection

Lenses move into one of the most technologically sensitive areas of the lab: the coating chamber.

Before coatings are applied, lenses undergo:

- Ultrasonic cleaning

- Plasma treatment

- Drying and dehydration cycles

These steps ensure the surface is perfectly prepared for adhesion.

Applying Premium AR, UV, and Blue-Light Coatings

Inside vacuum deposition chambers, multiple ultra-thin layers are added to create:

- Anti-reflective coatings for glare reduction

- Scratch-resistant layers for daily durability

- UV protection lenses for long-term eye health

- Blue light blocking technology for digital comfort

- Hydrophobic and oleophobic layers for easy cleaning

MIA LAB’s premium coating suite-such as Jade™, Sky™, and Full Protect™-is engineered to withstand heat and humidity common in Miami and South Florida, ensuring long-lasting durability with no peeling.

Step 5 – Edging & Finishing: Preparing the Lens for the Frame

Once coated, lenses move to the finishing area.

Precision Edging for Any Frame Type

Using advanced digital tracers, the lab reads the exact shape of the frame. Edging machines then cut the lenses to match:

- Full-rim frames

- Semi-rimless

- Drill-mount / rimless designs

- Wrap frames

- High-base curve sports eyewear

Trivex lenses and polycarbonate lenses-commonly used for impact resistance-benefit from controlled edging parameters to prevent micro-cracks.

Visual Marking and Final Adjustments

Technicians verify:

- Optical center alignment

- Seg height for progressive lenses for presbyopia

- Prism accuracy

- Edge smoothness

- Frame fit

This stage prepares lenses for the final and most important step: quality control.

Step 6 – Micron-Level Quality Control: Ensuring Optical Accuracy and Patient Comfort

Quality assurance defines the difference between an average product and a precision-engineered solution.

At MIA LAB, QC involves:

- Digital lensmeters with micron-accuracy

- Power verification for all meridians

- Mapping of progressive corridors

- Visual inspection under precision lighting

- Coating integrity checks

- Frame fit evaluation

Consistent QC is what lowers remake rates and improves patient satisfaction-especially for custom progressive lenses.

Learn more about MIA LAB’s QC standards:

👉 https://mialab.com/quality-control

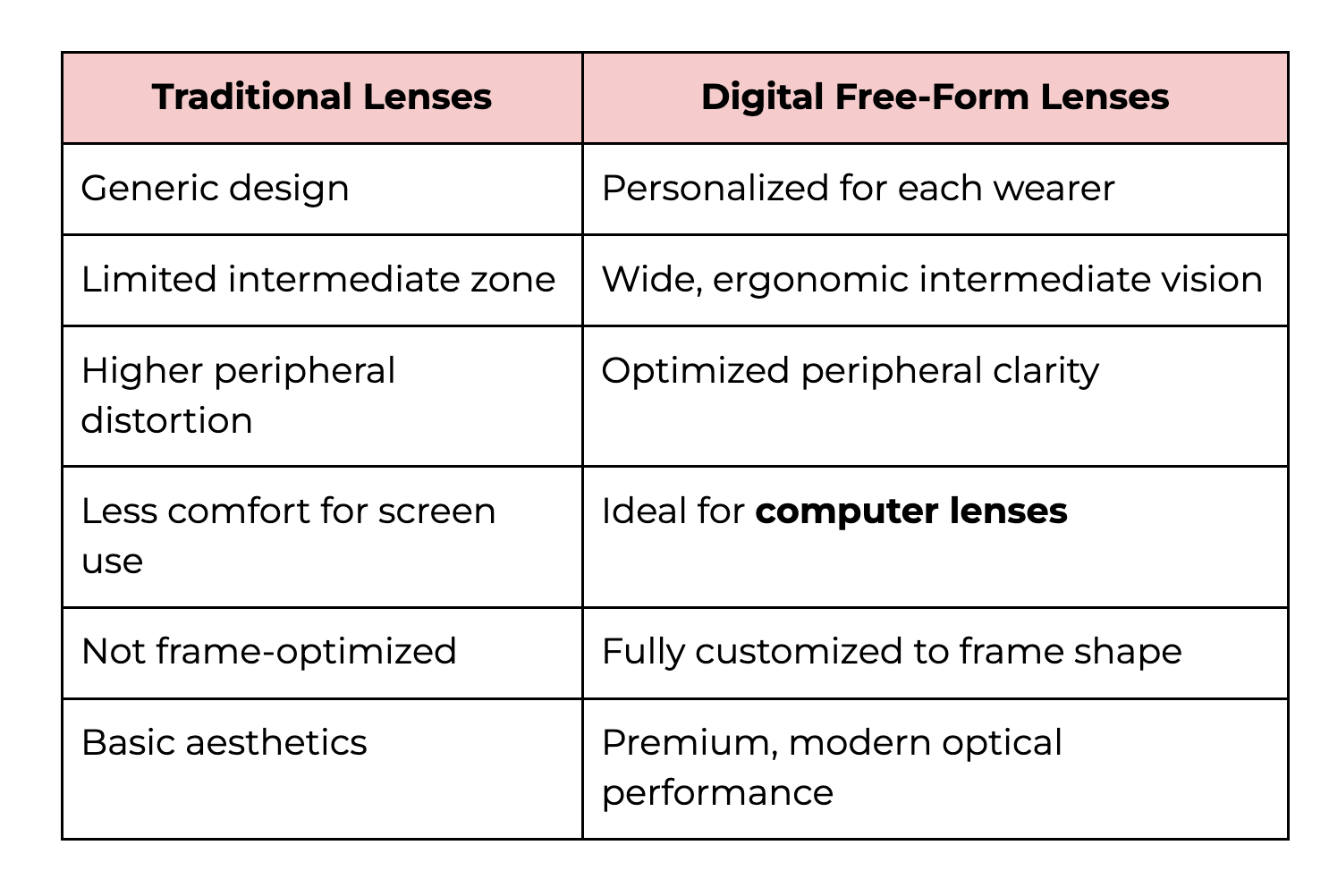

How Free-Form Lens Manufacturing Differs from Traditional Methods

This explains why modern practices increasingly choose labs specializing in digital surfacing and custom ophthalmic lenses.

Why Understanding the Process Matters for Optical Practices

Educating patients becomes easier when professionals understand exactly:

- How prescription lenses are made

- Why digital surfacing improves visual comfort

- Why coatings matter for durability and clarity

- Why free-form progressives adapt better

- How high-index vs polycarbonate lenses differ

- What sets a high-precision prescription lens lab in Miami apart from mass-production labs

This knowledge results in:

- Fewer remakes

- Higher premium-lens upgrades

- Increased patient loyalty

- Stronger practice reputation

Why Partnering with a High-Tech, Independent Optical Lab Matters

A technologically advanced independent optical lab – especially one operating locally, such as MIA LAB in Hialeah / Miami, Florida, offers major advantages:

- 24-hour turnaround on many wholesale optical lenses

- Advanced free-form technologies

- Premium coating options designed for Florida climate

- Bilingual support for Spanish-speaking clinics

- Personalized service unavailable at corporate labs

- Fast delivery across the Miami metro and South Florida area (Doral, Hialeah, Kendall, Broward)

This combination makes MIA LAB one of the strongest choices for independent optometrists seeking a reliable optical lab partner.

Ready to See This Process in Action?

Experience the precision and speed of a fully digital, high-performance lens lab.

Schedule a virtual lab tour or send a test job to see the workflow – from surfacing to finishing – and experience 24-hour turnaround firsthand.

- Explore the lab: https://mialab.com/

- View lens portfolio: https://mialab.com/lenses

- Browse coatings: https://mialab.com/anti-reflective-coating

A high-precision lab is more than a supplier – it’s an extension of your practice.